Spyder Engines

The Engine

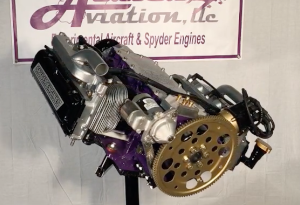

The 100 HP IFB engine that is currently available is the 100 Horsepower 170 cu. in. engine. It begins as a 1965-1969 Corvair 164 110 HP engine that is stripped down and modified to become an airworthy experimental aviation engine. The 120 HP Version is made of the same case but has other upgrades listed below.

The case is cleaned and checked for clearances. We install the IFB (Integral Front Bearing) housing and align it to the case. The crankshaft has the front steel hub and new gear installed, reground and nitrided for durability. It is reassembled with new bearings, camshaft, seals, forged pistons, reconditioned cylinders, reconditioned heads, rebuilt valve train, new 30 amp integrated rear alternator, starter, ring gear and much more.

The 120 HP IFB version of our Spyder engine will look very much the same as our 100 HP version. Most differences are internal. Instead of a reground original GM crankshaft it comes with a brand new counterweighted crankshaft with a 1/4" stroke. The cylinders are brand new .060 full finned cylinders with custom forged pistons and rods. The extra stroke and displacement cylinders bring the engine to 3.1L in size. We dont have to machine the heads or case for larger cylinders and therefore keep case strength where we need it. A 100 HP engine could be swapped out for the 120 with very little effort. We do include a large carburetor in our FWF kits for the 120 engine.

Once assembled the engine is installed on our custom made dynamometer to test run and monitor running parameters such as oil pressure, temperatures, rpms, and torque. These logs are kept on file for every engine we run. We check the oil for unusual contaminants after the test run.

They are beautiful engines and make for a clean installation into your airplane. The smoothness of the six cylinders and the safety that provides boosts your confidence as you fly. The low cost and ease of maintenance allow for a big savings throughout the life of the engine. All engines come with Maintenance and Service Manuals.

Integrated Front Bearing

IFB = Integral Front Bearing : Also commonly known as a 5th Bearing. A bearing mounted on the propeller end of a Corvair conversion engine to help support and absorb loads on the engine caused by the propeller.

Our Design = The reason our 5th bearing is called an integral front bearing is because we have integrated a steel propeller hub into the existing Corvair crankshaft. This procedure resolves many issues and simplifies the engine. Here are the Pros....

- The Crankshaft becomes a one piece unit. Once the propeller hub is installed onto the crankshaft it is treated as one unit. This includes grinding, nitriding, polishing and installation. This eliminates the need for safety shafts and hub bolts. As a consequence it is a lighter assembly.

- The thrust flange that carries propeller thrust loads is now located at the front of the engine, not at the rear. It is also larger in size.

- The main bearing and seal are locally available at auto parts stores for replacement purposes and come in a variety of sizes.

- The robust front housing is able to carry a very high load compared to any other 5th bearing design currently on the market. We will be able to use constant speed propellers on this design.

- This design also allows us to extend the propeller forward slightly to allow for improved cooling and lower cowling drag.

- Because of simplicity it's cost is very reasonable and actually less than others on the market.

As far as Cons.. They are relitively minor but are of importance to the dependability of the final product.

- Has to be initially assembled in-house. Because of the nature of the front housing, it needs to be bore aligned to the case in-house. Afterwards, the case can always be dissassembled and bearings changed without disturbing the alignment. It is a simple and low cost procedure. We typically have shortblocks ready to go.

- This may be a negative to those who have front starter setups. The IFB will only work with our rear alternator and starter setup. However, this allows the use of a 32 amp alternator and a starter setup that is easy to maintain due to off the shelf starter and ring gear. (SEE IRA) That is a PRO!

CURRENT FLIGHT HOURS ON THE IFB DESIGN: 2500 + (12/2014)

Integrated Front Bearing Assembly

Crankshaft with CNC'd Hub installed and reground. We use existing forged corvair crankshaft that have been magnafluxed, and inspected to begine this process. We also have brand new counterweighted crankshafts available in a stock and stroker version depending on horsepower requirements.

Crankshaft with CNC'd Hub installed and reground. We use existing forged corvair crankshaft that have been magnafluxed, and inspected to begine this process. We also have brand new counterweighted crankshafts available in a stock and stroker version depending on horsepower requirements.

Case with housing attached and crankshaft. The stock corvair case has been cleaned and fitted for the IFB housing. We can paint the case and other parts to your requirements.

Case with housing attached and crankshaft. The stock corvair case has been cleaned and fitted for the IFB housing. We can paint the case and other parts to your requirements.

Crankshaft and Camshaft installed into case half before closing. Here you can see the ample bearing surface and thrust flanges incorporated into the IFB. This 5th bearing design can handle higher loads and more safely than any other design out there. With the single piece hub it is now "locked" into the housing - no need for safety shafts or hub bolts. It cannot come loose. The front bearing and seals are from a Chevrolet 350 V8 - a common off the self item. See Video...IFB Teaser

need i frame with you tube link here. https://youtu.be/RTDlWSBQ-DU

Crankshaft and Camshaft installed into case half before closing. Here you can see the ample bearing surface and thrust flanges incorporated into the IFB. This 5th bearing design can handle higher loads and more safely than any other design out there. With the single piece hub it is now "locked" into the housing - no need for safety shafts or hub bolts. It cannot come loose. The front bearing and seals are from a Chevrolet 350 V8 - a common off the self item. See Video...IFB Teaser

need i frame with you tube link here. https://youtu.be/RTDlWSBQ-DU

A finished short-block all torqued and ready to ship. It includes the rebuilt case, crankshaft, a new camshaft and gear, plus all new bearings. A typical Shortblock assemble costs about $2600.00. Call about more information.

Noteworthy: The prototype of this 5th bearing design we made is still flying today. It first saw service in 2007 and has hundreds of hours on that airframe. Since then there have been several aircraft in service that are flying with the IFB Conversion with no failures to date. Because of its design it can be maintained on the field with no need to return to Azalea Aviation. Due to its simplicity and cost effectiveness we decided some time ago that all our engines will come equipped with the IFB.

A finished short-block all torqued and ready to ship. It includes the rebuilt case, crankshaft, a new camshaft and gear, plus all new bearings. A typical Shortblock assemble costs about $2600.00. Call about more information.

Noteworthy: The prototype of this 5th bearing design we made is still flying today. It first saw service in 2007 and has hundreds of hours on that airframe. Since then there have been several aircraft in service that are flying with the IFB Conversion with no failures to date. Because of its design it can be maintained on the field with no need to return to Azalea Aviation. Due to its simplicity and cost effectiveness we decided some time ago that all our engines will come equipped with the IFB.

Pricing

Manuals

Engine Videos

4th Engine Test

This is the fourth run of this engine (2 hrs. break in)

Engine Walk around

A walk around of another engine during test run...love the sound!

Sonex Installation

Engine Running in a Sonex Installation

KR2S flying

Saberwing Owner, Bill's KR2S flying with a Spyder Engine

3D Spyder Engine Video

3D view of the Spyder Corvair Engine

*** WARNING *** As a small business let us caution you that you are purchasing an EXPERIMENTAL engine and/or parts and as such it does not carry liability or warranty as may be typical. We do guarantee our labor and parts other than normal wear for a year. Premature wear or damage can occur if non-standard installations or carelessness happens during the installation and break-in. As such the purchaser assumes all liability for the installation and use of the engine. If there are any perceived or indications of problems, please contact us right away so we can help you.